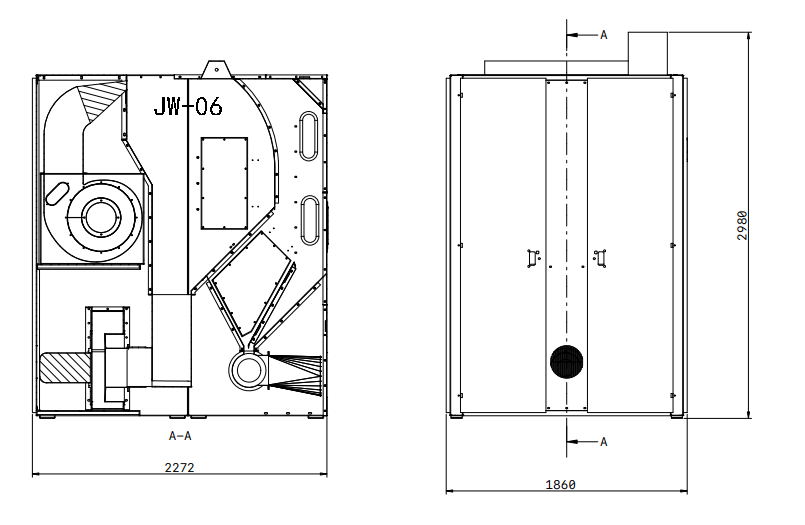

Dust Collector

JW-06/151/1057

The air-cleaning machine is suitable for all grades of cotton fibers and is the final cleaning step in the carding process. It can remove fine dust and impurities from the fibers that have been well carded. These machines can effectively remove fine dust and impurities from the fibers that have been well carded, which can greatly reduce the number of broken yarns caused by fiber contamination.

Main Features

1. The dust removal process is unique: after the fiber bundle collides with the mesh plate, it is completed by the airflow action, which has the characteristics of not damaging fibers, high dust removal efficiency, and flexible process flow configuration.

2. Flexible speed control: The cotton blower uses a variable-frequency inverter motor with no-load speed adjustment, which can be set to the required speed according to the system pressure requirements to ensure that the system air volume and pressure are adjustable and the system is stable.

3. Reduced maintenance: The optimized cotton inlet pipeline has high operational stability and effectively reduces the need for maintenance.

Specifications

| The air volume of the cotton fan (m3/h) | 4000~4800 |

| Filter area (m2) | 3.6 |

| Dust exhaust air volume (m3/h) | 3500 |

| Air pressure at the dust exhaust outlet (Pa) | -50~-150 |

| Installed power (kw) | 8 |

| Dimension (mm) | 2180 x 1860 x 2646 |

| Net weight of the whole machine (kg) | 1450 |

Send us a message!

Feel free to leave your inquiry or interest. We’ll get back to you promptly.

Follow on Social