Auxiliary Equipments

Cotton Condenser &

Vertical Fiber Separator

JW-030 & JW055-160

JW055 series vertical fiber separator is mainly used for separating dust and short fibers from the cotton. It is erected before the vibrating chute,the reserve silo or the fine opener in the scutching line.

1.Cotton fiber revolves while it passes through the fiber separator. The dust and short fiber,functioned by the centrifugal force, is sucked through gird to the dust exhaust pipe.

2.Meanwhile the fiber is better mixed during material drop.

Specifications

| Type | FA055-160 |

| Motor power (kw) | 4 |

| Overall dimension (mm) | 1260 x 900 x 1300 |

| Production (kg/h) | 1000 |

| Air displacement (m3/h) | 3300~5000 |

| Diameter of the cotton entry pepe (mm) | Φ 300 |

2-way distributor

JW-221

Either JW221A or JW221B is erected with the material transporting pipe and used in the “one system two material” blowing-carding process.

Specifications

| Working diameter(mm) | Φ 300 |

| Max.working pressure (Mpa) | ≤1 |

| Inter pipe specification(mm) | Outer Φ 8×1 |

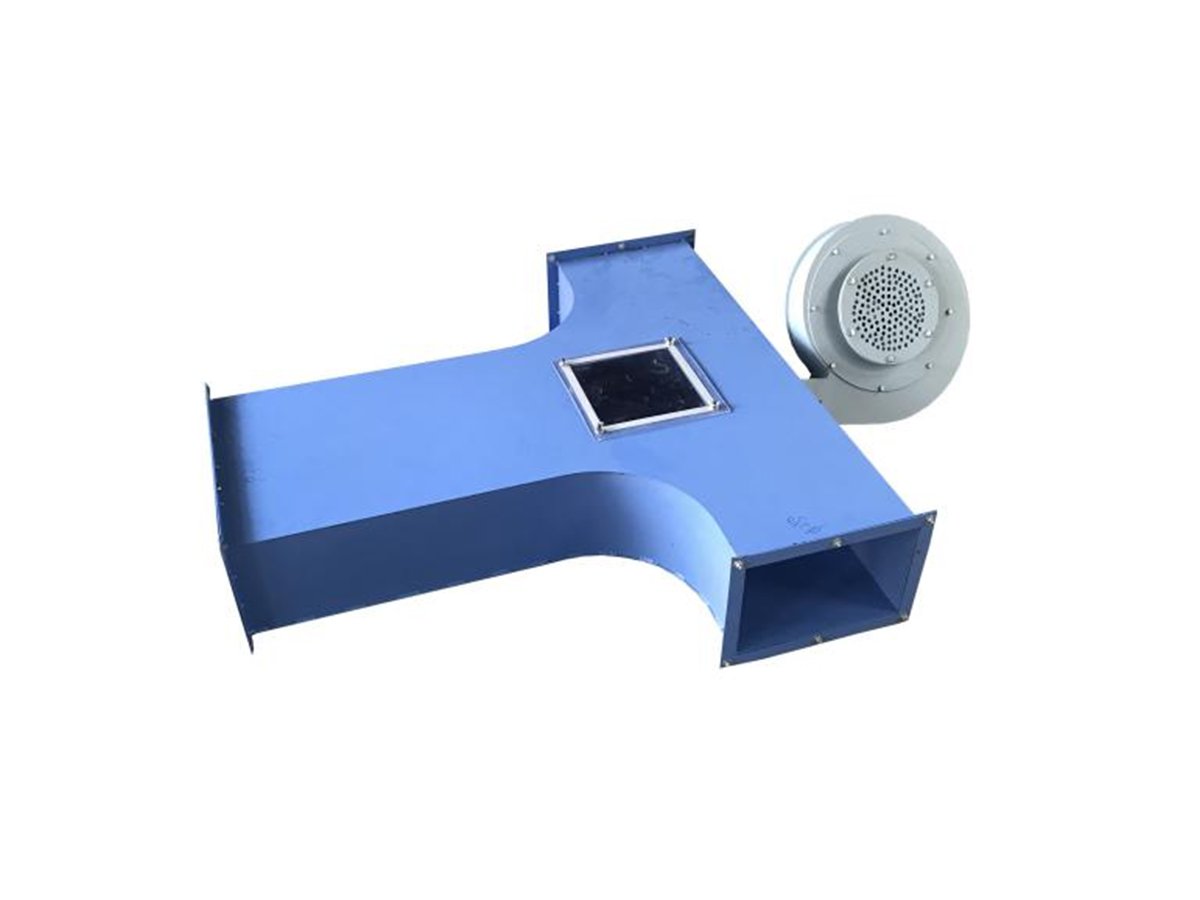

T-shape Distributor

JW-202A

JW202A is used in two-way distributing system between transportation fan and chute feeder,whose function is to even disteibuting cotton from transportation fan to two transportation ducts.

Specifications

| Fan air pressure (pa) | 2000 |

| Fan air volume (m3/h) | 600 |

| Fan air power rate (kw) | 0.55 |

| Overall dimension (mm) | 1776 x 1300 x 536 |

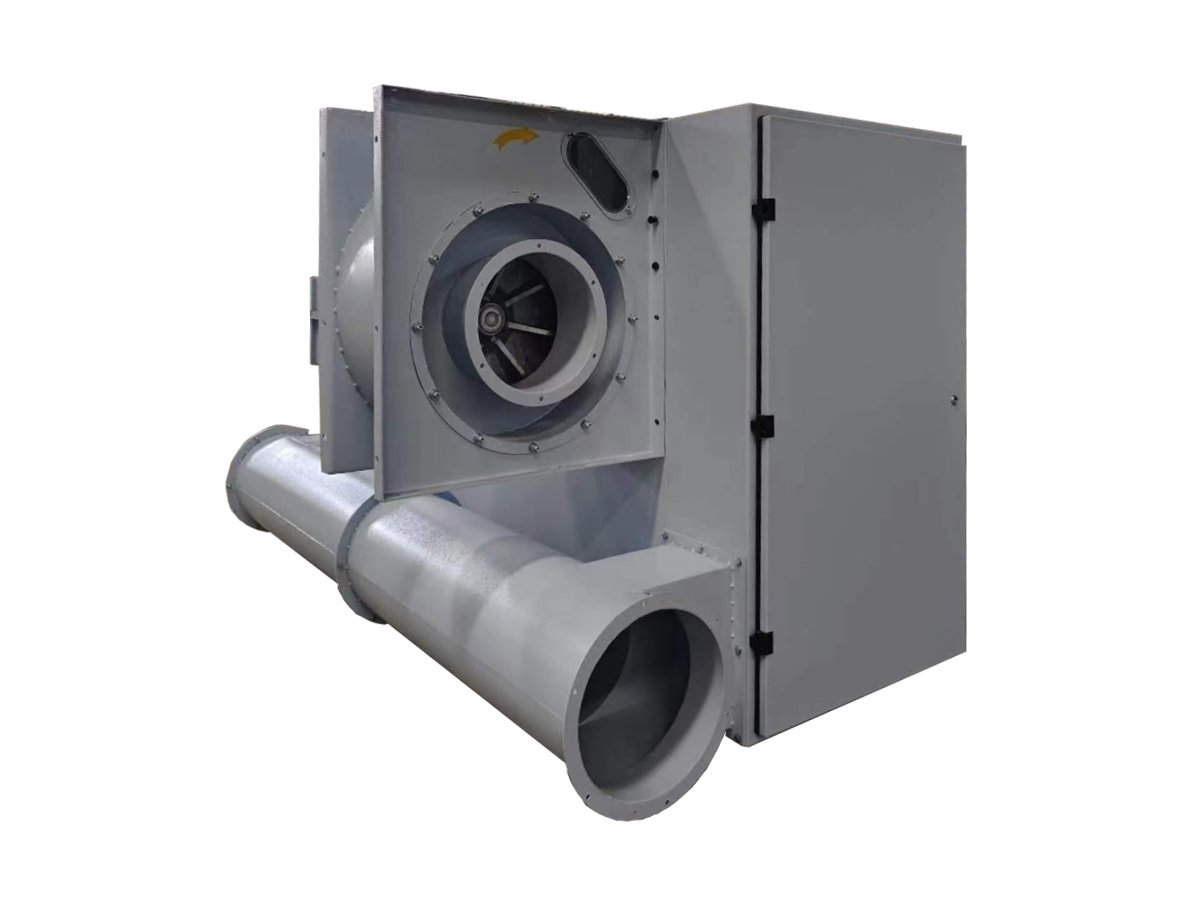

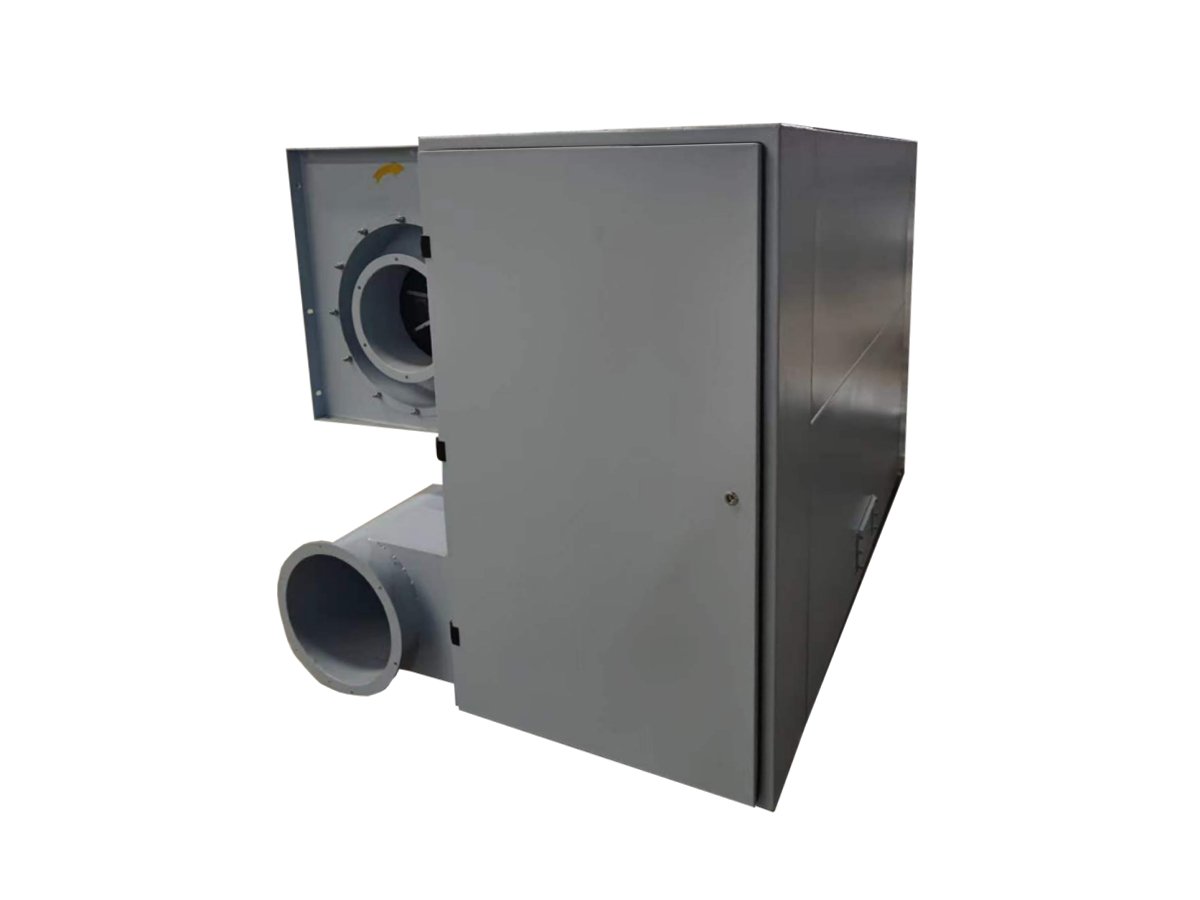

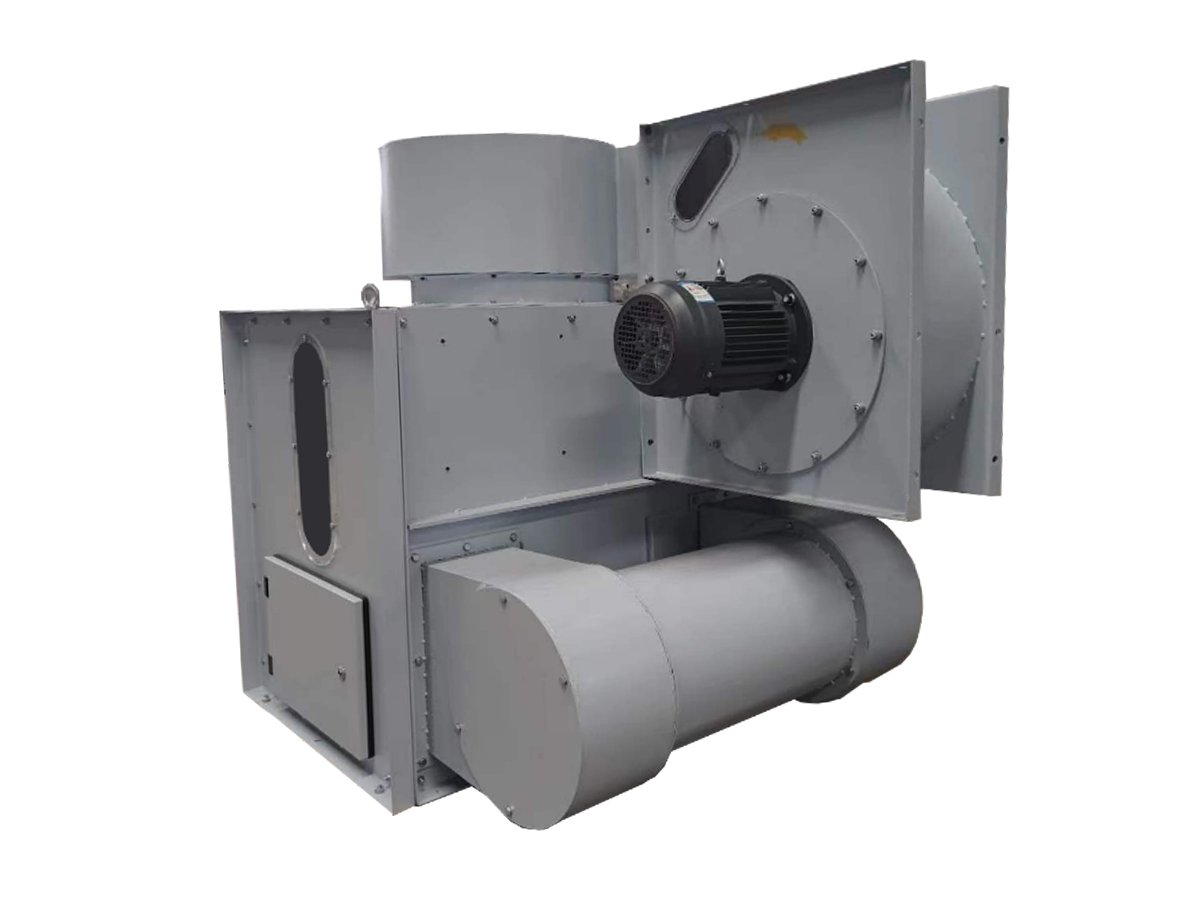

Transport Fan

The FT transport fan is used to transport raw material from the front different single machine o the next one.those motors can control the pressure and volume of the air in the duct accurately. It adopts straight-blade aluminum-alloy impeller which has a smooth oxygenated surface and features no sparkle,no block and no adhesion of fiber.its surface is painted with plastics and it have a good antirust performance.

Specifications

| Type | JW026E/FT240 | JW026F/FT245F | JW026D/FT247B |

| Air volume (m3/h) | 5320 | 6042 | 6500 |

| Speed (r/min) | 1440/2890 | 1440/2890 | 1480/2900 |

| Power (kw) | 4 | 4/5.5 | 7.5/9/11 |

| Overall dimension (nn) | 820 x 702 x 720 | 820 x 702 x 720 | 1222 x 928 x 780 |

Tail Yarn Cleaning Machine

- The tail yarn cleaning machine is mainly used in the coarse and fine coupling system to automatically clean the tail yarn and waste flowers adsorbed on the sticky strips on the used yarn tubes of the fine yarn machine, for direct use in the automatic production of the yarn machine. It can also be used separately as a machine for cleaning yarn spools.

- Motor power 4kw, transmission motor power 0.75kw, single cleaning of 8 pipes

- Efficient and labor-saving, reliable, convenient, fast and safe operation.

Main features

- This equipment has a dedicated device that can unwind defective rolls. This device can unwind the tail yarn with a maximum diameter of 170 millimeters.

- Will not cause damage to the tube.

- The machine has a simple design and compact structure 1380*890*900 (mm).

- Process one roving tube in 19-23s, with 8 tubes processed at a time, approximately 24 tubes processed per minute, and approximately 1440 tubes processed per hour.

Bridge Magnet

JW225B

Main Features

- This machine is the main equipment used in the carding system to detect and remove metal objects mixed in fibers, and is used to protect the normal operation of the subsequent equipment after the cotton picking machine in the carding system.

- This device is installed between the reciprocating cotton gripper and the JW247 (B) cotton conveying fan.

- Main technical specifications: The external dimensions of the strong magnet are length x width x height=560mm x 225mm x 720mm. Equipped with 2 pieces of 560mm * 225mm * 170mm square to round cotton conveying pipes, magnetic field strength inside: 1700GS.

Send us a message!

Feel free to leave your inquiry or interest. We’ll get back to you promptly.

Follow on Social